First orcinus system for die casting installed and commissioned

Ten temperature control circuits, up to 180 °C (356 °F), robust protection architecture for the specific demands of die casting

In the week before Christmas, we were able to give our customer and ourselves a genuine first: the first orcinus system for die casting was successfully installed and commissioned.

In die casting, controlling the thermal balance is a decisive factor for part quality, scrap rate, and cycle time. In practice, an incorrect mold temperature is considered one of the most significant primary sources of process deviations.

This is exactly where orcinus comes in. orcinus is not a temperature control unit. It is a monitoring and digitalization system for mold temperature control. It makes flow rate and temperature visible, traceable, and analyzable for each circuit, providing the basis for reproducible processes and fast root cause analysis.

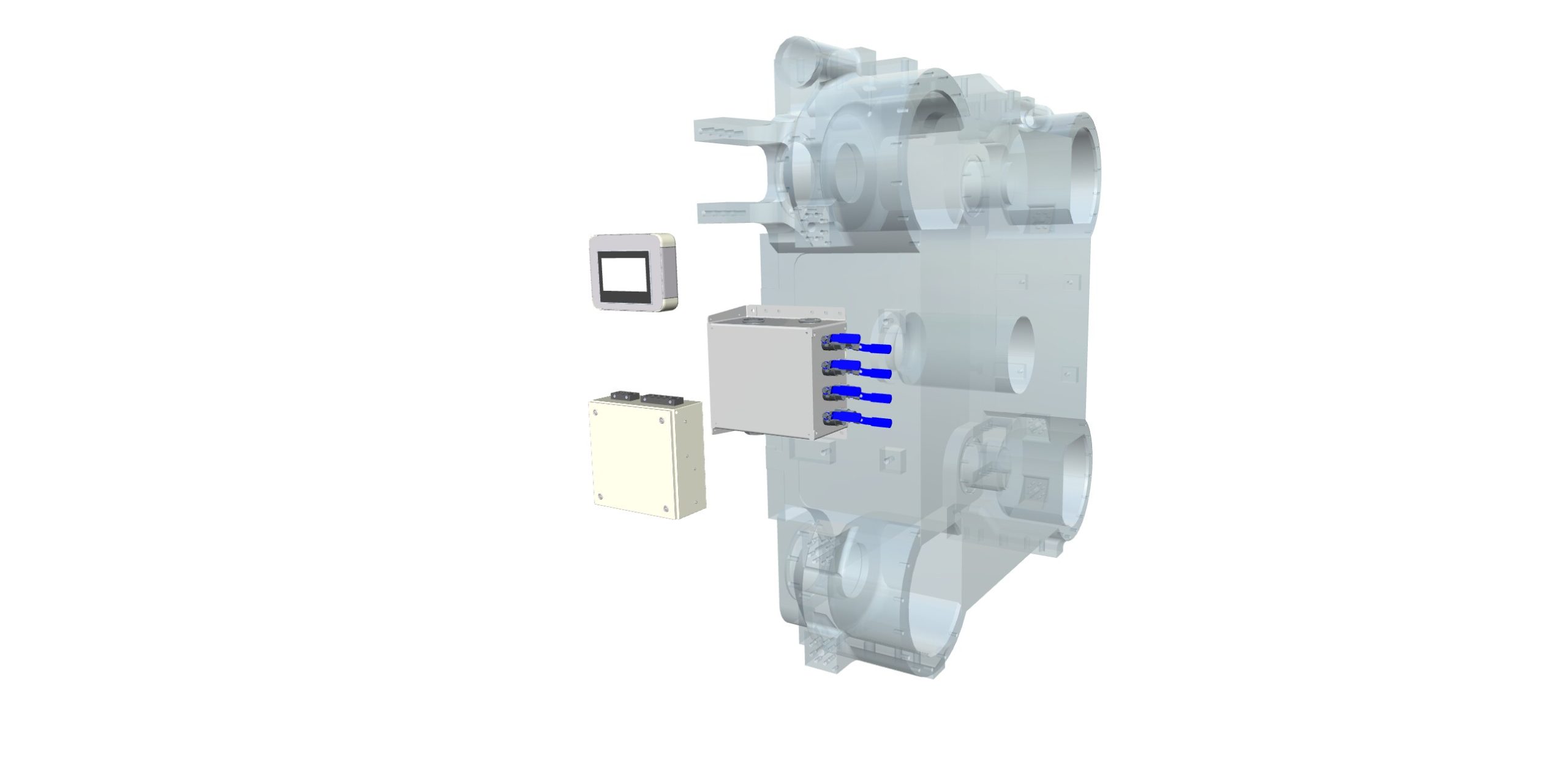

The first die casting installation includes a total of ten temperature control circuits. The circuits are distributed across two manifolds. In this project, the system is designed for temperatures up to 180 °C (356 °F). Water is used as the heat transfer medium, and oil is also possible as a cooling medium.

Measurement follows the proven principle: the flow is detected contactlessly via dual ultrasonic sensors, and the temperature is measured via sensors in the process. This enables continuous monitoring of all circuits and turns the data into a reliable basis for stable production.

Specifically for die casting, the entire setup has been engineered consistently for protection and robustness. Compared to standard applications, all components are significantly better shielded against external influences:

- the distributor is completely closed to provide permanent protection for the sensor technology and the distributor itself

- sensor displays are placed inside the e box for protection, not in the manifold

- stainless steel hoses are used for the piping

- the cables are installed in a protective metal pipe

With this design, we address typical die casting conditions such as thermal load changes, spray and media exposure, and demanding environments around the machine. Technical publications on mold temperature control underline how critical stable operating temperatures and a controlled thermal balance are for die life and process reliability.