The orcinus temperature control systems from enesty GmbH digitize flow and temperature monitoring in injection moulding processes. The orcinus systems are based on the principle of parallel distribution. The cooling or temperature control medium is distributed from a central point to several circuits evenly. This central supply ensures a constant temperature in each connected circuit, which is essential for the consistent quality of the manufactured components.

3 reasons to make your flow digital

cycle time

reduction

quality

improvement

process

optimizing

an overview of the orcinus systems

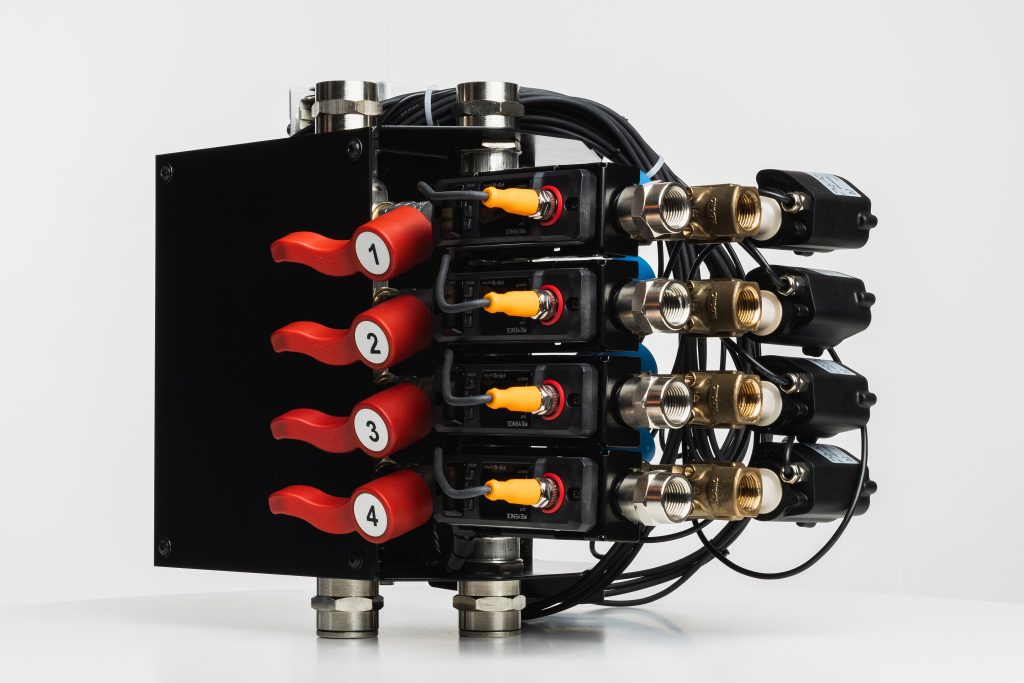

orcinus orca

… is a maintenance-free temperature control system. The double ultrasonic measurement enables non-contact and precise measurement of temperature and flow rate. The sensor does not come into contact with the temperature control medium. Designed for temperatures up to 180 °C (356 °F).

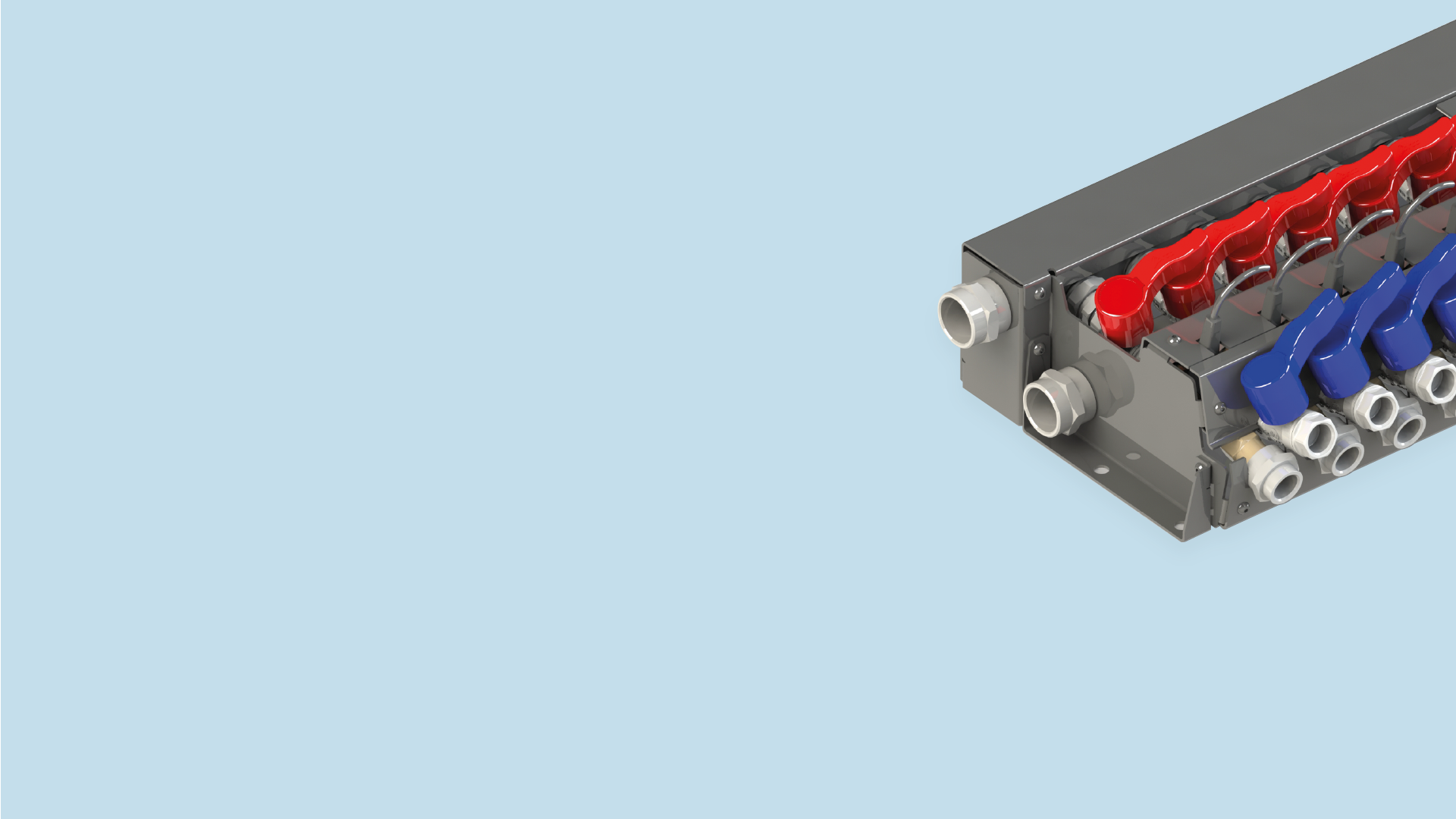

orcinus smartshark

… is our compact temperature control system. Consisting of high-quality materials and a robust stainless steel manifold block, we ensure cost-efficient monitoring of flow rates. Designed for temperatures up to 100 °C (212 °F).

a plus

in performance

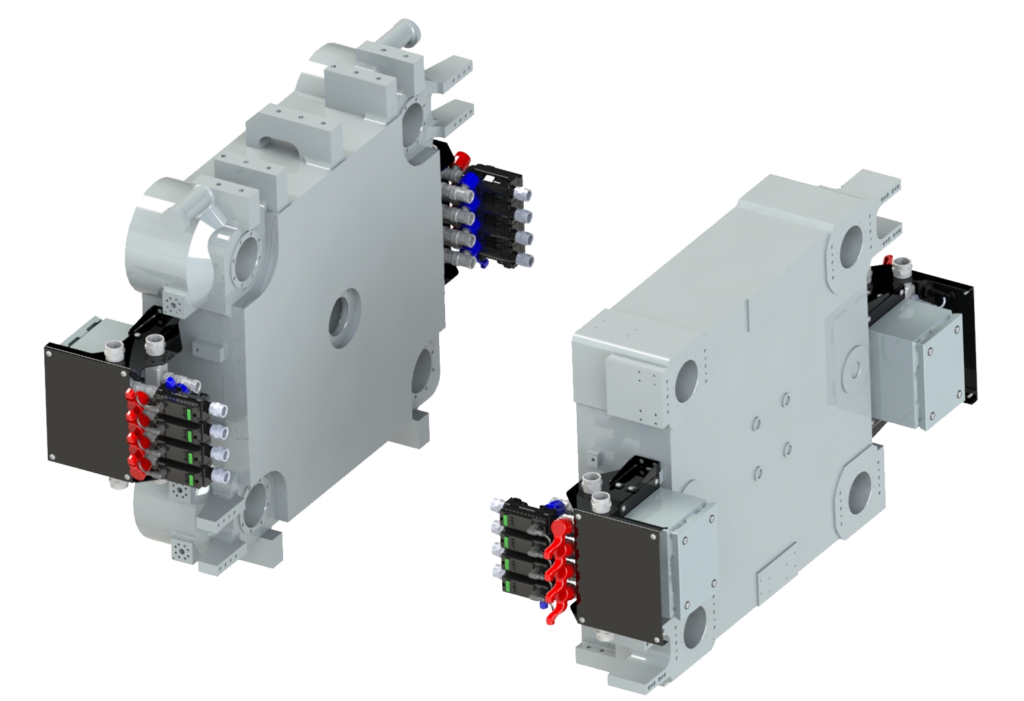

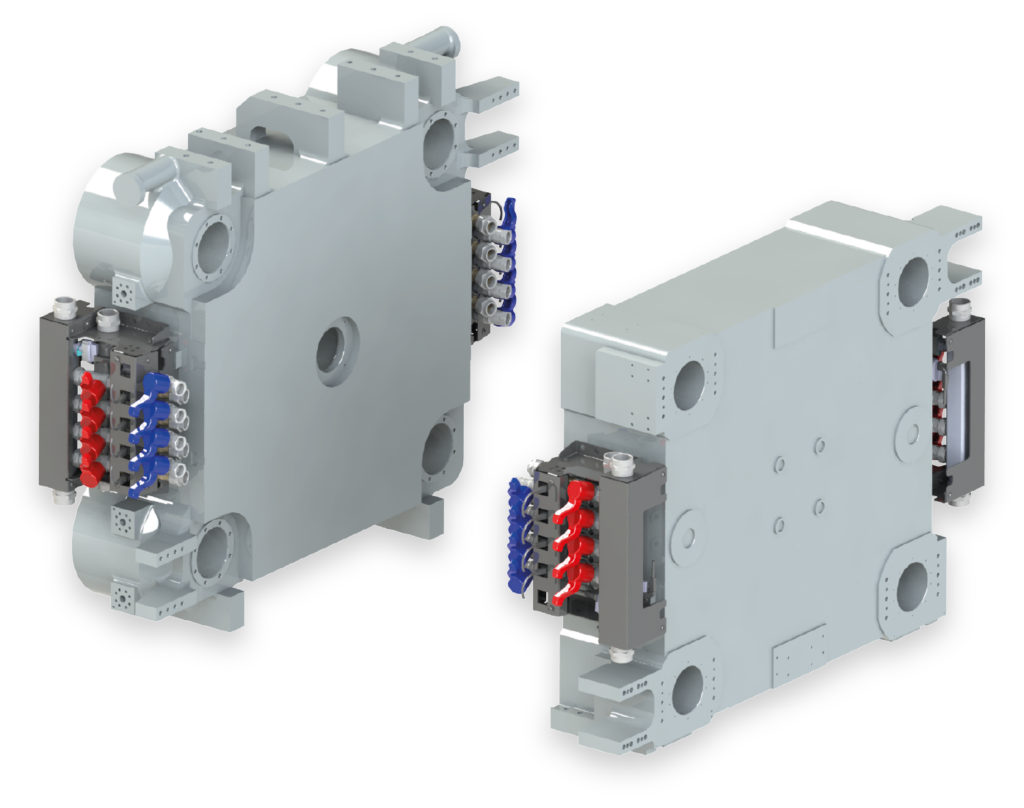

orcinus orca and orcinus smartshark as an adjustable plus variant

Our plus systems have one control valve per circuit, allowing precise control of the desired flow rate, fixed valve opening or temperature differential per circuit. Designed for temperatures up to 160 °C (320 °F) for our orcinus orca systems and 100 °C (212 °F) for the orcinus smartshark systems.

temperature control units

high line

The high line stands for maximum ease of use with an intuitive 7″ multi-touch display and powerful 32-bit controller. Ideal for demanding applications up to 180 °C and 230 l/min.

eco line

The eco line combines energy efficiency with sustainability: speed-controlled high-efficiency pumps enable electricity savings of up to 92 %. Suitable for processes up to 180 °C and 230 l/min.

flex line

The flex.line offers maximum flexibility: modularly configurable with heating outputs of up to 72 kW, flow rates of up to 350 l/min and temperatures of up to 160 °C. Perfect for individual requirements in extrusion, roller temperature control and process engineering.

we also offer …

beluga

The smart beluga system uses multi-stage electronic differential pressure monitoring to detect dirty filters at an early stage.

multi beluga

With multi-beluga, several flows can be monitored separately. For optimum monitoring of even complex filter systems and reliable flow to all consumers.

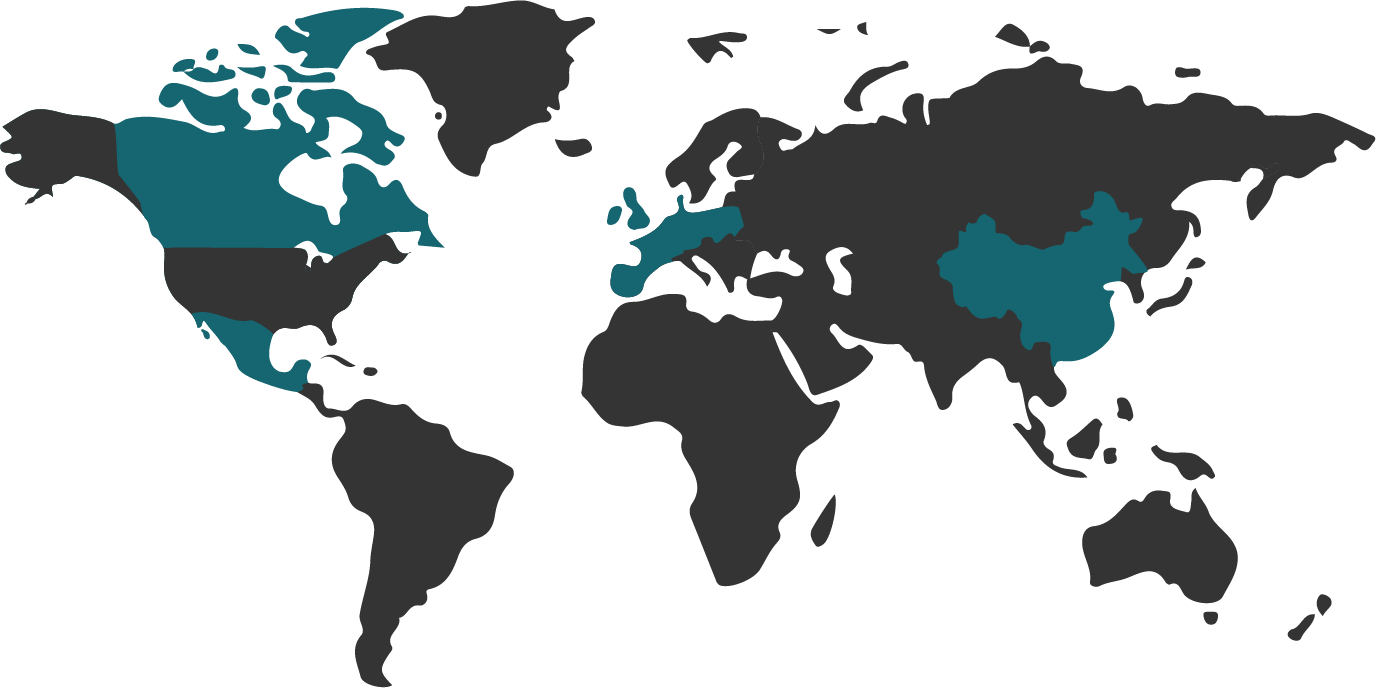

we are represented worldwide

Numerous industrial companies around the world are already benefiting from the advantages of our temperature control systems in the processing of plastic products.

orcinus in

action

In addition to plastics processing, our products are also used in metal processing. Here, processes can be optimized to save valuable cycle time and energy while at the same time achieving quality improvements.