temperature control units

Process reliability and efficiency in temperature control

Our high-performance temperature control units are the “powerful engine” of our system. Experience the highest quality for industrial applications up to 180°C. We have put together a selection of three possible relevant temperature control units for you below. If you are interested in other temperature control units, please feel free to contact us.

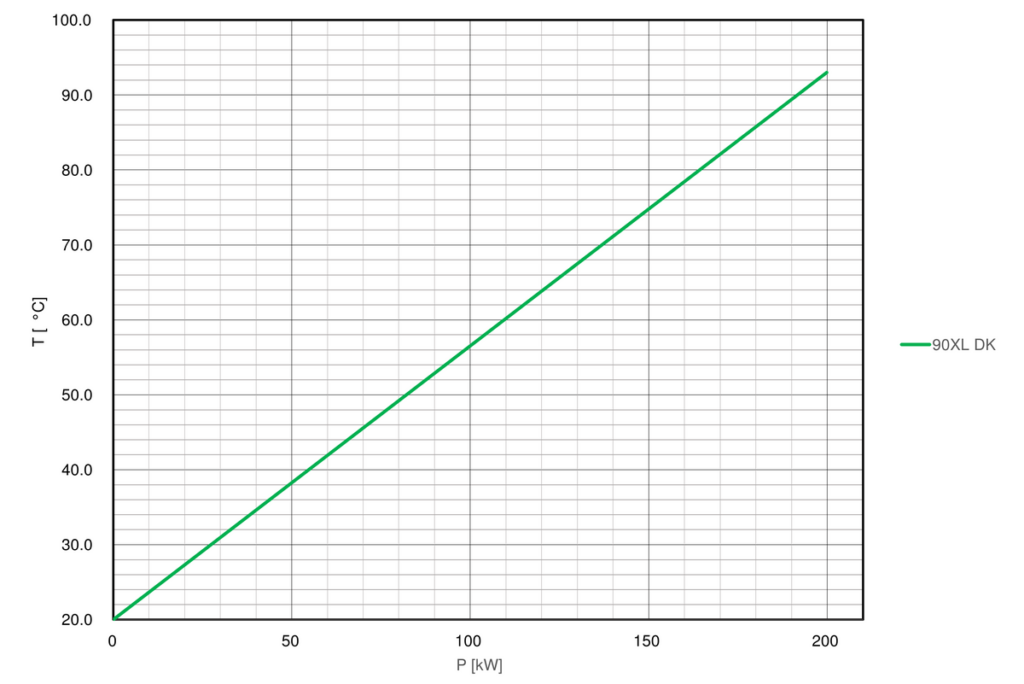

90XL

The temperature control unit for water for applications in plastic injection molding and industrial applications up to 90 °C

- RT200 control system

- pump with high flow rate: 200 l/min

- high heat output up to 60 kW

- direct cooling

more information about 90XL

| heat transfer medium |

flow temperature |

heat output at 400V |

cooling capacity |

pump capacity/type |

| water |

90 °C |

20 / 40 / 60 kW |

|

|

|

|

|

|

|

|

|

|

|

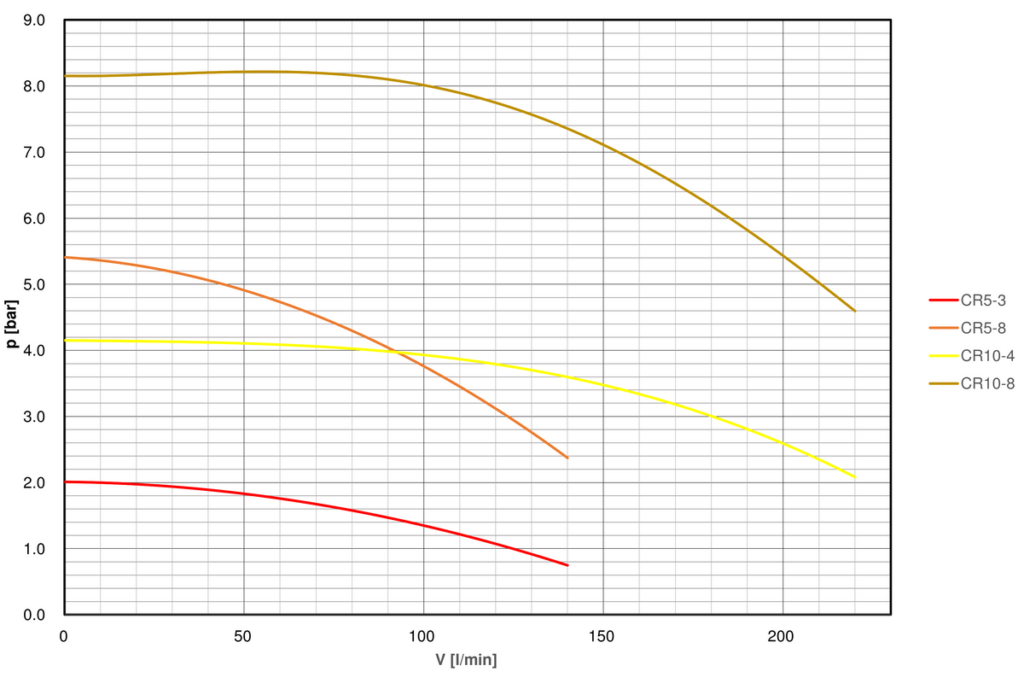

| CR 10-4 |

140 l/min |

0.55 kW |

|

|

|

|

|

| CR 10-8 |

140 l/min |

0.55 kW |

|

| flow temperature |

|

|

| max. |

°C |

90 |

| heat transfer medium |

|

water |

| filling quantity |

l |

36,5 |

| expansion space |

l |

5,5 |

| heat output at 400V |

kW |

20 / 40 / 60 |

cooling capacity

|

kW |

160 |

| cooler |

|

DK |

| at flow temperature |

°C |

80 |

| at cooling water temperature |

°C |

20 |

| pump capacity/type |

|

| CR 5-3 |

CR 5-8 |

CR 10-4 |

CR 10-8 |

|

| max. flow rate |

l/min |

|

| power consumption |

kW |

|

| pressure max. |

bar |

|

| control system |

|

RT100 / RT200 |

| measurement type (standard) |

|

Pt100 |

| connection voltage |

V/Hz |

|

| connections |

|

|

| forward/return |

|

G1 1/2″ IG |

| cooling water network |

|

G3/4″ |

| protection class |

|

IP54 |

| dimensions W/H/D |

mm |

436/1357/1387 |

| weight |

kg |

229-275 |

| color |

RAL |

9006/7016 |

| ambient temperature |

|

|

| max. |

°C |

40 |

| continuous sound pressure level |

db (A) |

< 70 |

- manual valve in the flow and return

- filter in the cooling water circuit

- medium water circuit made of stainless material

- automatic water refill

- solid-state relay (SSR) instead of heating contactor

- device in protection class IP54

- direct cooling (DK)

- RT200 control system

- electronic flow measurement

- leakage-free pump

- RT100 control system

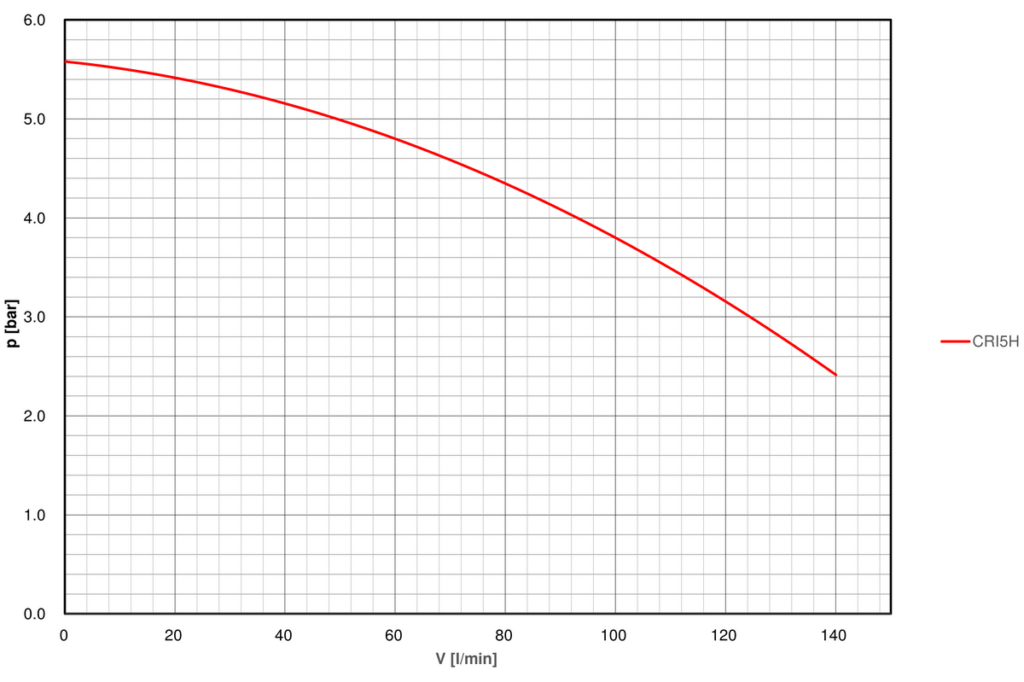

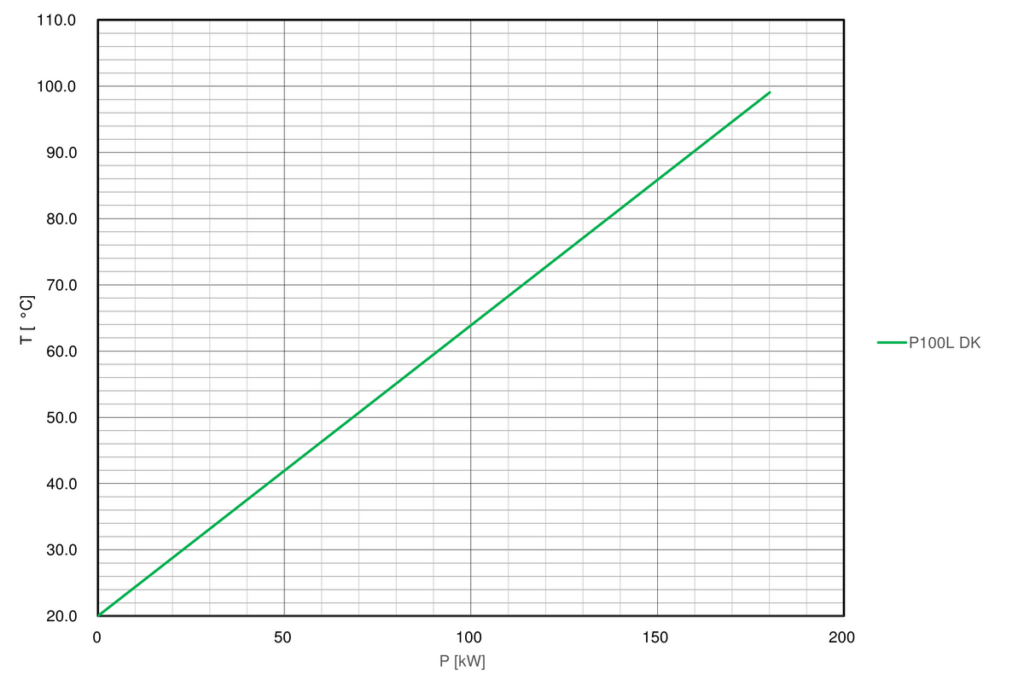

P100L

The pressurized water temperature control unit for applications in plastic injection moulding and industrial applications up to 100 °C.

- RT200 control system

- pump with high flow rate: 140 l/min

- pressure control

- direct cooling: maximum cooling capacity

- solid-state relay instead of heating contactor

more information about P100L

| heat transfer medium |

flow temperature |

heat output at 400V |

cooling capacity |

pump capacity/type |

| water |

100 °C |

17 / 34 / 51 kW |

|

|

| flow temperature |

|

|

| max. |

°C |

100 |

| heat transfer medium |

|

water |

| filling quantity |

l |

12 |

| expansion space |

l |

– |

| heat output at 400V |

kW |

17 / 34 / 51 |

cooling capacity

|

kW |

160 |

| cooler |

|

DK |

| at flow temperature |

°C |

90 |

| at cooling water temperature |

°C |

20 |

| pump capacity/type |

|

CRI5 |

| max. flow rate |

l/min |

140 |

| power consumption |

kW |

1.1 |

| pressure max. |

bar |

5.4 |

| control system |

|

RT100 / RT200 |

| measurement type (standard) |

|

Pt100 |

| connection voltage |

V/Hz |

| 380-415 V, 50 Hz |

440-480 V, 60 Hz |

|

| connections |

|

|

| forward/return |

|

G1″ / 60° / Konsus |

| cooling water network |

|

G1/2″ |

| protection class |

|

IP54 |

| dimensions W/H/D |

mm |

350/967/1366 |

| weight |

kg |

170 |

| color |

RAL |

9006/7016 |

| ambient temperature |

|

|

| max. |

°C |

40 |

| continuous sound pressure level |

db (A) |

< 70 |

- solid-state relay (SSR) instead of heating contactor

- filter in main circuit

- direct cooling (DK)

- device in protection class IP54

- medium water circuit made of stainless material

- automatic water refill

- filter in the cooling water circuit

- pressure gauge for system pressure

- RT200 control system

- electronic flow measurement

- RT100 control system

P180L

The pressurized water temperature control unit for plastic injection moulding and industrial applications up to 180 °C

- RT200 control system

- pump with high flow rate: 140 l/min

- low-scaling “SK” cooling system

- pressure control

- solid-state relay instead of heating contactor

more information about P180L

| heat transfer medium |

flow temperature |

heat output at 400V |

cooling capacity

|

pump capacity/type |

| water |

180 °C |

17 / 34 / 51 kW |

|

|

|

|

|

|

|

| flow temperature |

|

|

| max. |

°C |

180 |

| heat transfer medium |

|

water |

| filling quantity |

l |

12 |

| expansion space |

l |

– |

| heat output at 400V |

kW |

17 / 34 / 51 |

cooling capacity

|

kW |

|

| cooler |

|

|

| at flow temperature |

°C |

|

| at cooling water temperature |

°C |

|

| pump capacity/type |

|

CRI5 |

| max. flow rate |

l/min |

140 |

| power consumption |

kW |

1.1 |

| pressure max. |

bar |

5.4 |

| control system |

|

RT100 / RT200 |

| measurement type (standard) |

|

Pt100 |

| connection voltage |

V/Hz |

| 380-415 V, 50 Hz |

440-480 V, 60 Hz |

|

| connections |

|

|

| forward/return |

|

G1″ / 60° / Konus |

| cooling water network |

|

G1/2″ |

| protection class |

|

IP54 |

| dimensions W/H/D |

mm |

350/967/1366 |

| weight |

kg |

170 |

| color |

RAL |

9006/7016 |

| ambient temperature |

|

|

| max. |

°C |

40 |

| continuous sound pressure level |

db (A) |

< 70 |

- solid-state relay (SSR) instead of heating contactor

- manual valve in flow and return

- medium water circuit made of stainless material

- automatic water refill

- filter in the main circuit

- filter in the cooling water circuit

- patented low-scaling cooling system (SK)

- pressure gauge for system pressure

- device in protection class IP54

- RT200 control system

- electronic flow measurement

- RT100 control system