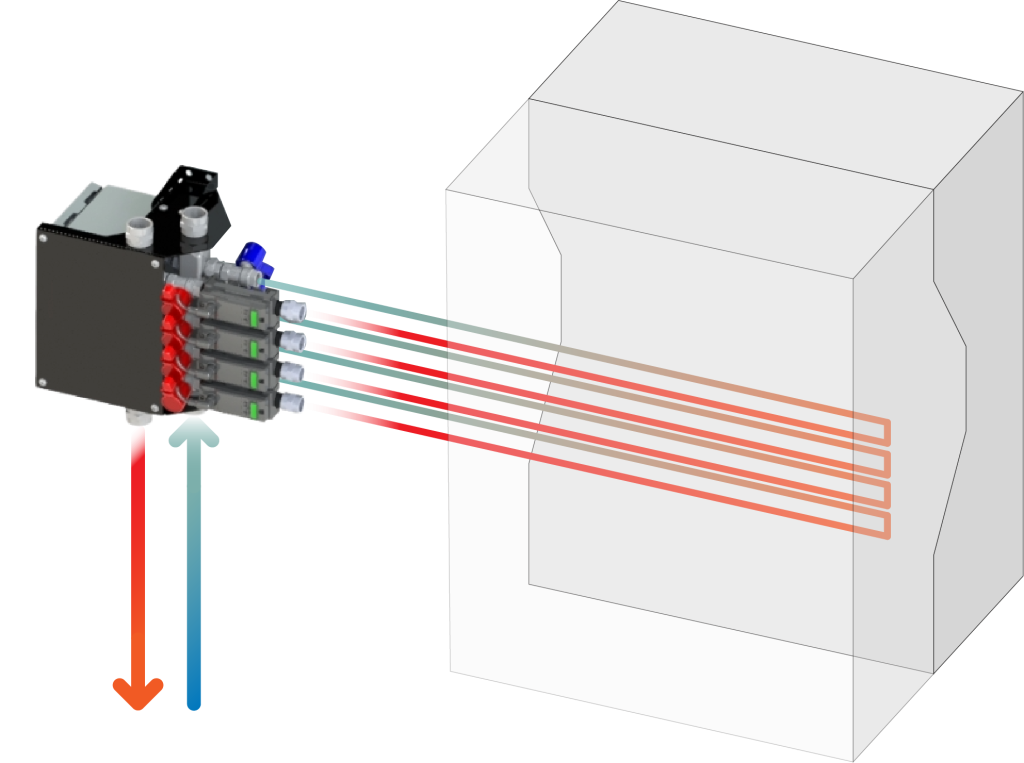

The orcinus temperature control systems from enesty GmbH digitize flow and temperature monitoring in injection moulding processes. The orcinus systems are based on the principle of parallel distribution. The cooling or temperature control medium is distributed from a central point to several circuits evenly. This central supply ensures a constant temperature in each connected circuit, which is essential for the consistent quality of the manufactured components.

How do you know what condition

the water in your tool actually has?

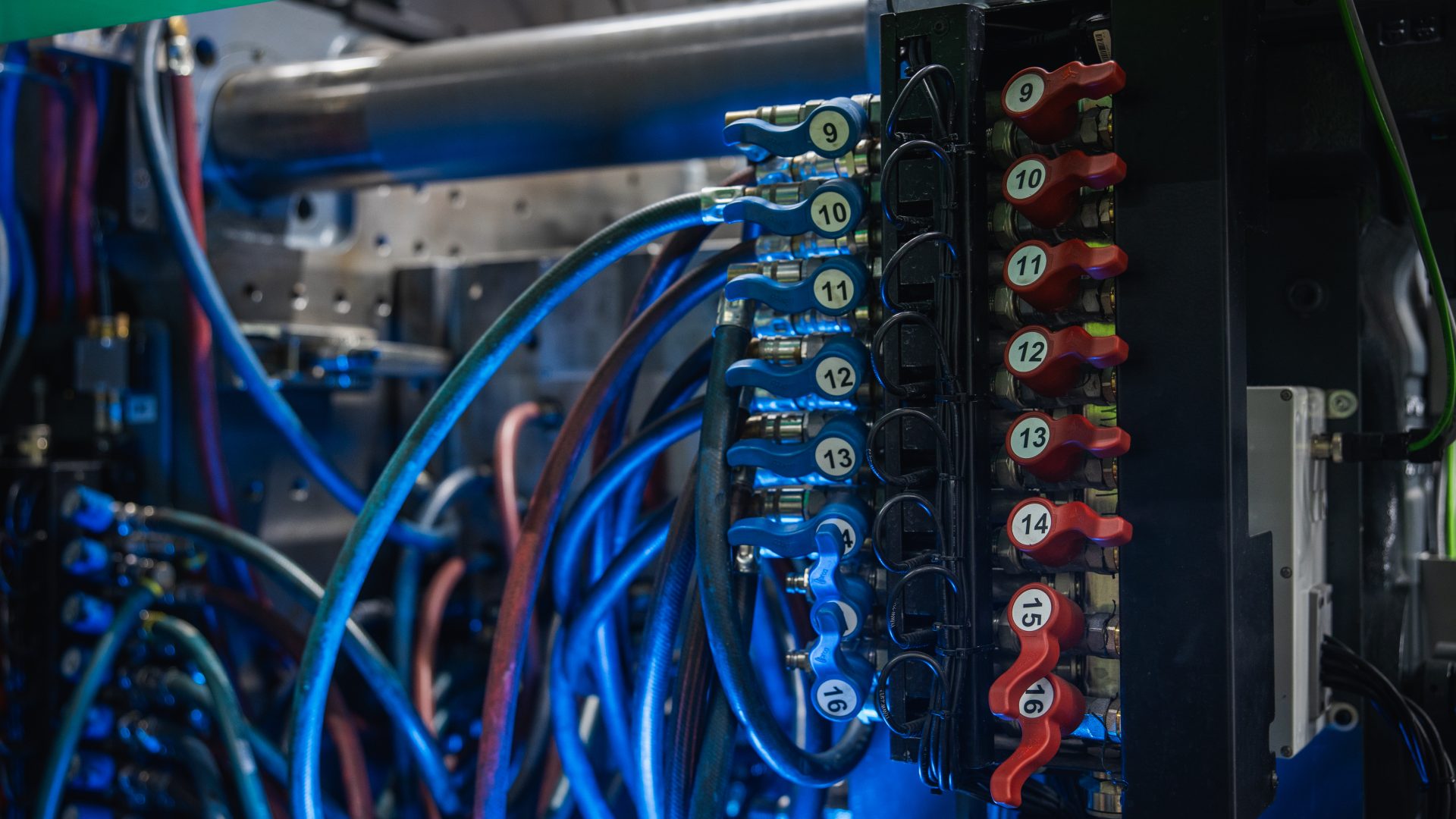

In many processes, it is not clear what is happening inside the cooling channels. Just measuring the external temperature of the mold or looking at the total flow rate is not enough.

Blocked cooling circuits, temperature differences, or undetected flow losses can significantly reduce the quality of your components, increase production times and energy consumption.

parallel distribution +

digital monitoring

3 reasons to make your flow digital

cycle time

reduction

quality

improvement

process

optimizing

facts from reference projects

10 – 20 %

shorter cooling times

Thanks the parallel distribution and digital monitoring of temperature

and flow, each individual cooling circuit is optimally supplied.

5 – 10 %

shorter cycle times

Constant temperatures reduce the cooling time and waste,

which directly reduces the overall cycle time.

30 %

less changeover time

Custom tool recipes and additional functions like the

blow-out function enable faster tool changes.

overview of orcinus systems

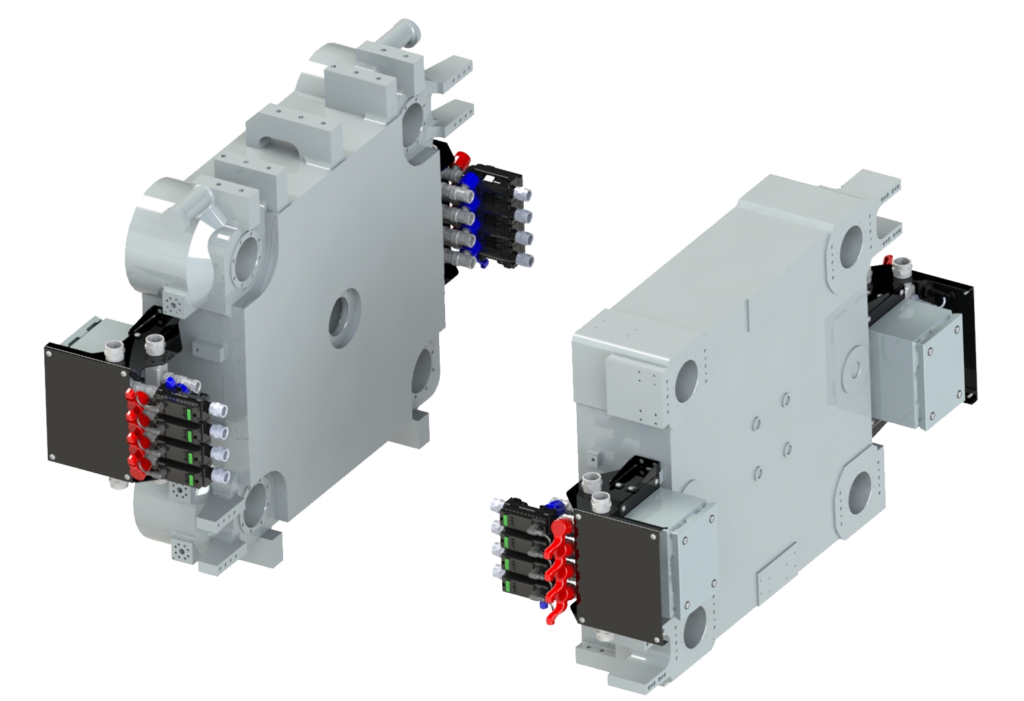

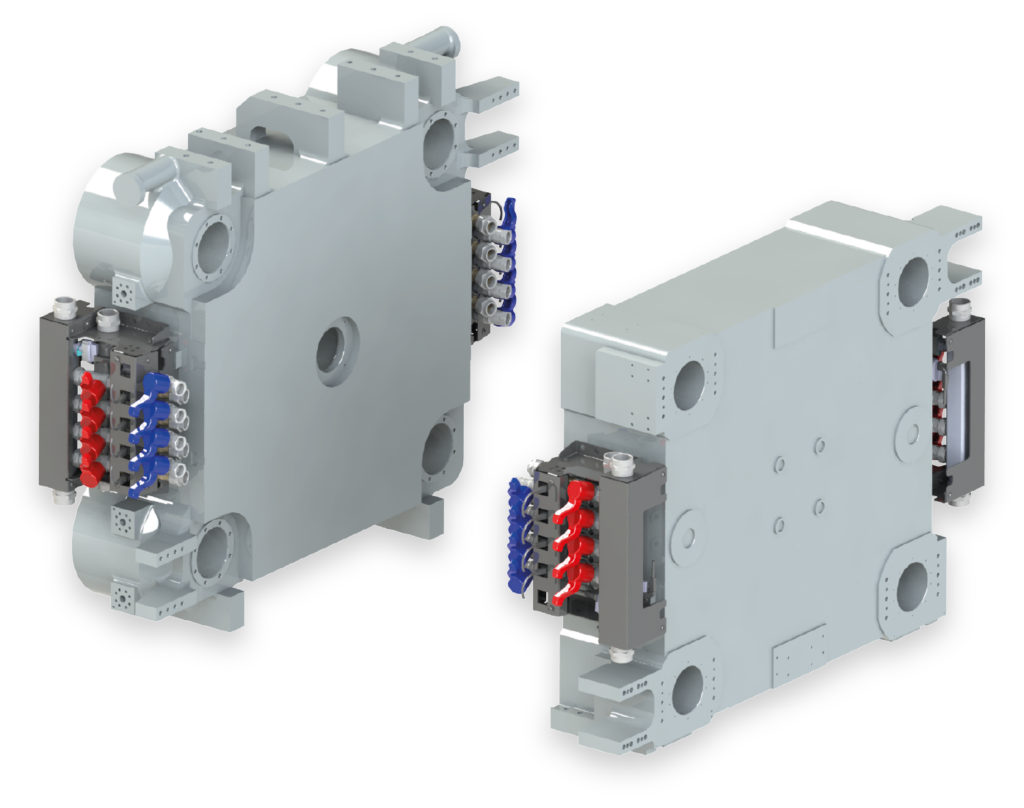

orcinus orca

… is our maintenance-free temperature control system. The dual ultrasonic measurement enables contactless and precise measurement of temperature and flow. The sensor does not come into contact with the temperature control medium. Designed for temperatures up to 180 °C (356 °F).

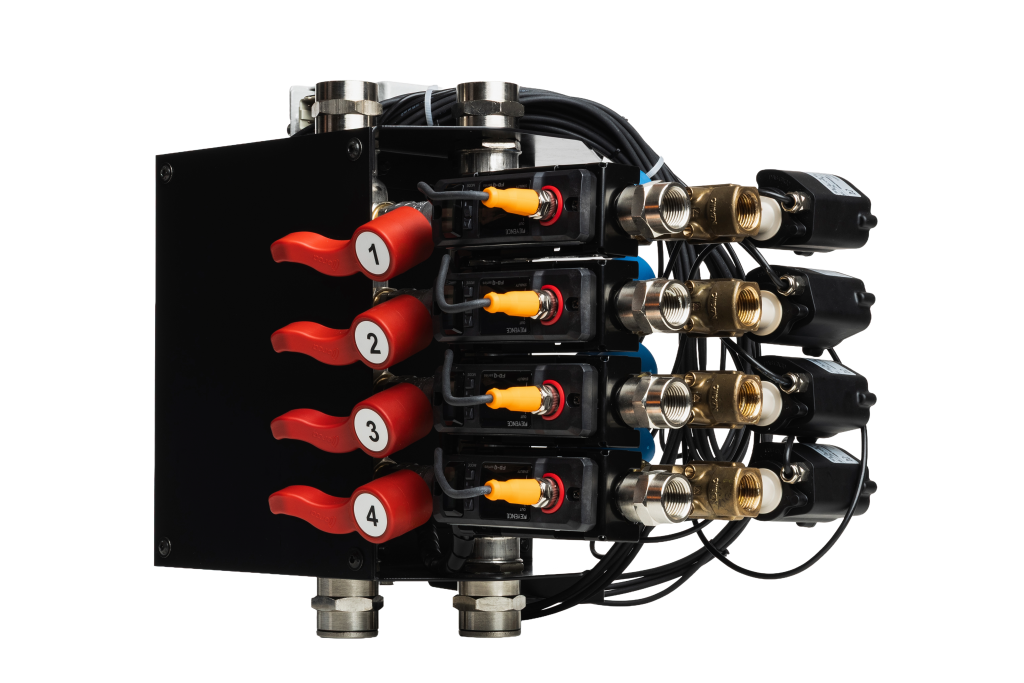

orcinus smartshark

… is our compact and space-saving temperature control system. Made from high-quality materials and featuring a robust stainless steel manifold block, we guarantee cost-effective monitoring of flow rates. Designed for temperatures up to 100 °C (212 °F).

a plus

in performance

orcinus systems as an adjustable plus variant

Our plus systems are additions to orcinus orca and orcinus smartshark. With one control valve per circuit, they enable precise control of the flow rate or temperature difference per circuit.

we also offer…

beluga

Contaminated filters are one of the most common reasons for process problems. The beluga system digitally monitors filter conditions, reports contamination at an early stage and thus provides reliable protection against failures – sustainably and with low maintenance costs.

multi beluga

The multi beluga upgrades the established beluga technology: instead of just one filter it is possible to monitor several filters in parallel. This makes the system ideal for highly advanced production facilities where process reliability and energy efficiency are top priorities.

temperature control units

Together with our global partners, we offer the right solution for every application – powerful, efficient, and optimally integrable into orcinus systems.