follow the flow

maintenance free

No filters, no contamination, no maintenance.

Once installed, orcinus monitors the flow of water or

oil reliably and for a long time.

contactless

A double ultrasonic sensor enables the contactless

and precise measurement of the

flow rates of your temperature control media.

simple and intuitive

orcinus can be easily integrated into many

industrial many industrial systems. Operation

is neither complicated nor cumbersome.

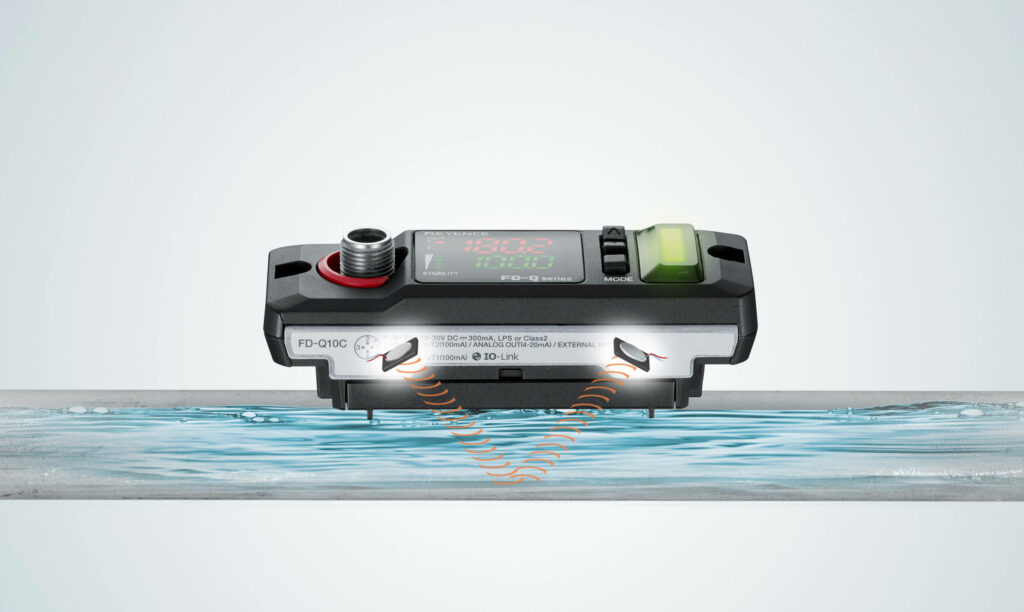

contactless measuring principle

The heart of this system is a double ultrasonic sensor,

which can measure the temperatures of water and oil up to

180 degrees. It uses the Delta-T detection principle,

to determine the flow rate by measuring the time difference between the transmission and reception of ultrasonic signals

in and against the direction of flow. This time difference

reflects the flow rate and remains stable thanks to the use of two ultrasonic signals, regardless of external factors such as temperature fluctuations.

intuitive

Everything at a glance – the manifold block communicates easily with our display and informs you about your flow rates. The display has the following advantages:

- digital monitoring of temperature, flow rate and pressure (optional)

- many interfaces included

- can be integrated into injection molding machine

- mold data records can be saved

- alarm outputs included

- tolerance specifications for temperature, flow rate and pressure (optional)

individually

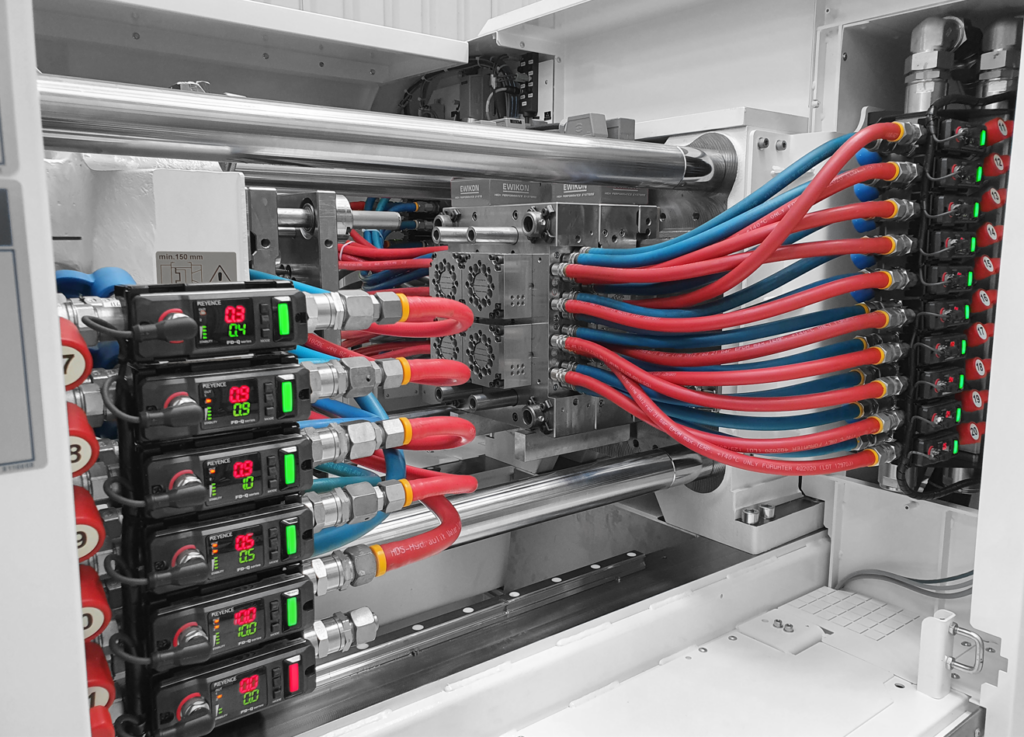

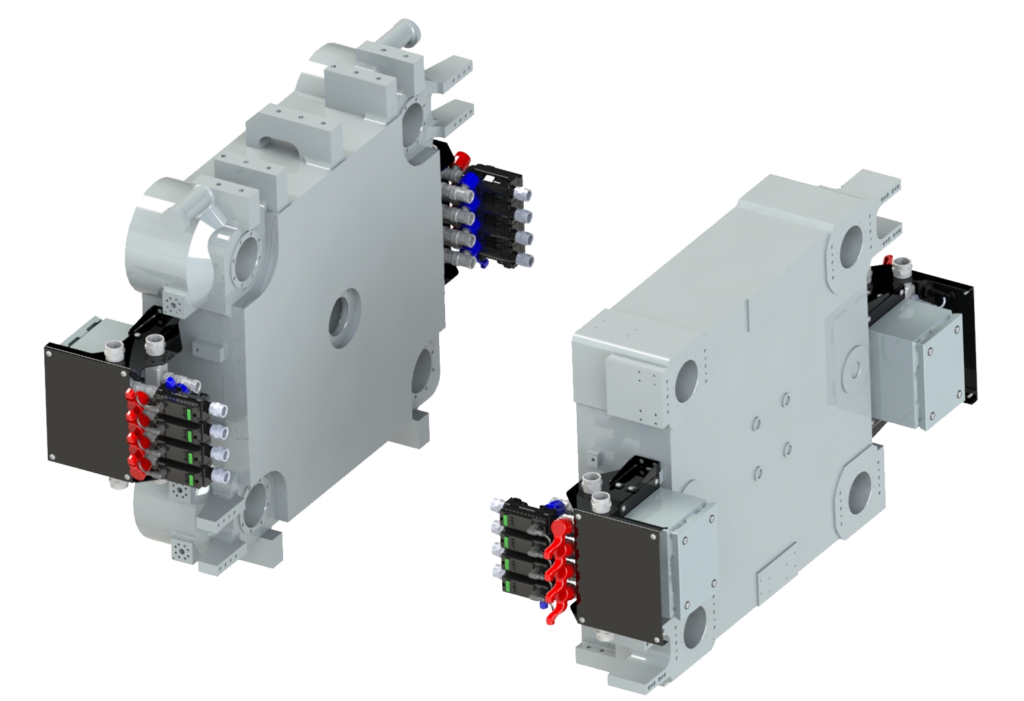

orcinus offers you the option of optimizing your process with 2-144 circuits. The division takes place in distributor blocks with 2, 4, 6, 8, 10 or 12 circuits. We install orcinus with a maximum of 20 blocks on your mold and thus reduce important cycle times.

Systeme

orcinus standard

orcinus slim

orcinus max

number of ciruits

2-8

2-8

8-12

collective forward & return flow

1 inch

1 inch

1,5 inch

control unit

–

operable from one side

–

maintenance free &

- contactless measuring principle – no contact with the medium

- not susceptible to contamination, so filter technology can be dispensed with.

- acid is no problem thanks to the stainless steel distributors

- insensitive to vibrations

- individual division of the circuits ensures exact allocation of the problem source

high performance

mold temperature control next level

Our orcinus can even be used at high temperatures. For flow media with temperatures up to 180 degrees Celsius, we have developed orcinus 180. This system uses particularly powerful sensors are used in this system. The manifold block consists of highly temperature- and pressure-resistant components.

components.

you cannot cool your injection mold

faster and more precisely

The use of our systems …

- reduces the pressure loss

- enables an increased flow rate in the individual circuits

- increases the cooling effect and heat exchange in the mold

- reduces the cooling time and thus the cycle time

- brings transparency to the process

- increases process reliability

- reduces maintenance costs for temperature control and mold

- lowers production costs

overview of our orcinus system

The orcinus system is based on the principle of parallel distribution. The control unit, distribution block and sensor components are optimally matched to the application in the manufacturing industry.

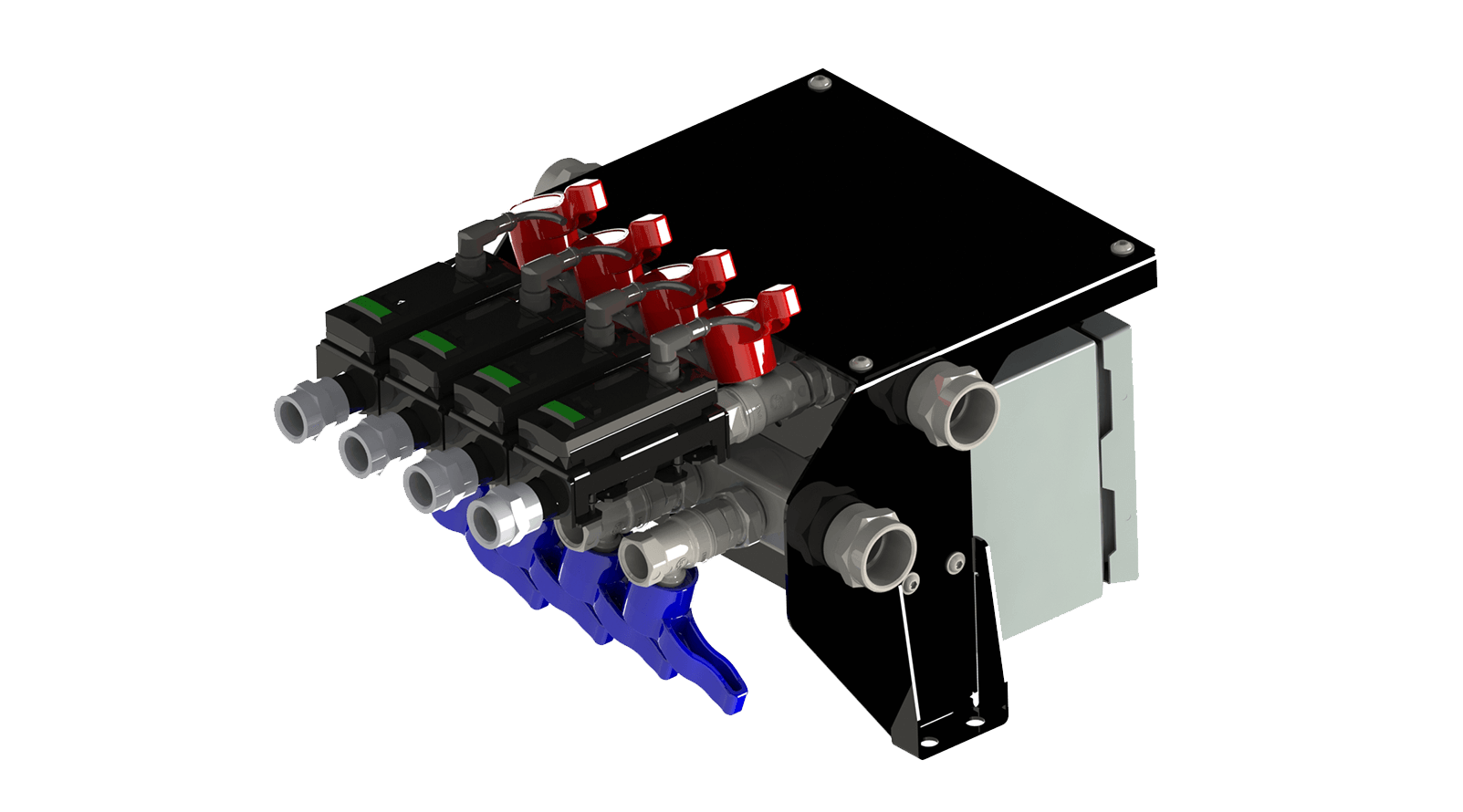

distribution block

- Optimum dimensioning without narrowing the cross-section

- Any installation position

- 1 inch continuous nominal width without cross-sectional constriction

- Large volume flow due to collective flow and collective return at each manifold

- Fault prevention: exact allocation of the problem source through individual division of the circuits

- Temperature and flow measurement for each circuit

The flow rate is a decisive factor for an optimized cooling and cycle time. The orcinus manifold block impresses with its optimum dimensions without narrowing the cross-section. Depending on the available space, the block can be integrated vertically or horizontally into the production machine.

The individual circuits are equipped with ½ inch connections and the central inlet and outlet with 1 inch connections. All wetted components are made of stainless steel and brass. The temperature resistance is 120 degrees Celsius, for the orcinus 180 series at 180 degrees Celsius.

sensor

- Double ultrasonic sensor (measuring range 1 – 30 l/min per circuit, other measuring ranges on request)

- Non-contact, precise measurement

- Signal strength adapts to the degree of soiling

- Flow rate display directly on the sensor (LED status display: green for OK and red for NOK)

- IP67 standard guarantees operation even under the most adverse conditions

We only use the highest quality and most modern components for orcinus. This applies in particular to the double ultrasonic sensor. The sensor measures the time it takes for an ultrasonic signal to travel from point A on the sensor to point B. As the flow rate increases, the signal is accelerated so that less time is required to transmit the signal from A to B.

The sensor calculates the current flow rate based on the relationship between the time taken and the flow rate. It sits outside the medium and measures very precisely – even under the most adverse operating conditions thanks to the IP67 standard. Equipped with LED status lights, it indicates at the point of use whether the minimum flow rate is guaranteed. Furthermore, the measured values are transmitted to the control unit where they are clearly displayed.

control unit

- Intuitive operation thanks to large touch display

- Many interfaces included

- Can be integrated into machine control system

- Tool data records can be saved

- Alarm outputs included

- Extensive history can be called up

- Tolerance specifications for temperature and flow rate

The top priority in the development of our control system was simple operation in order to provide users with comprehensive information intuitively. The touch fields are large and clearly laid out. This means they always have an overview of the individual temperature control circuits and can read and monitor the temperatures and flow rates at a glance.

Minimum and maximum limit values for temperature and flow rate can be entered for each circuit and saved for more than 500 tool data records. Deviations are clearly logged on the alarm page and are available for quality control and process optimization. Alarm outputs to the injection molding machines allow users to maintain control of their process at all times.

The control system has 3 operator levels. Various languages can be selected so that the system can also be used internationally. Extensive interfaces round off the high-quality control system. USB, Ethernet and OPC UA are available at no extra cost.